This is the second installment in a series of blog posts on the oil and gas industry. It will explore topics such as data delivery, trends in the industry and the evolution of oil and gas networks.

This is the second installment in a series of blog posts on the oil and gas industry. It will explore topics such as data delivery, trends in the industry and the evolution of oil and gas networks.

If you are in the network infrastructure industry, then you know how important physical layer is for the endless demand for capacity and bandwidth. Nowhere is this more evident that in the oil and gas market. It is helping drive the momentum for the industry’s next technological advancement in network evolution.

To really understand how a “living infrastructure” solves network challenges, it is best to look at how this cycle works. The oil and gas industry spans a vast geography, with critical elements into the supply chain, starting with on-and off-shore production locations. Production includes the following processes:

- Drilling, extraction and recovery of oil

- Shipping from remote operations sites to storage areas that serve the engineering area for crude distribution

- Delivering of crude through delivery lines or pipelines

SEE ALSO: Physical Layer Relevance in the Oil and Gas Market

Once refined fuel is ready for use, it is transported to terminals. This is the final staging point for refined fuel before point of sale.

This scenario illustrates how to connect the unconnected through wireline and/or wireless solutions, and is critical to evolving with this vertical market. An important thing to remember is that productivity gains exist when innovative networking communication solutions can be deployed beyond the remote sites to head offices. By enabling those issues with vital physical layer solutions, we assist in increasing productivity, efficiency and reducing expenses.

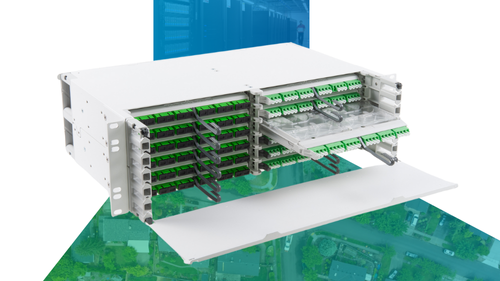

CommScope’s wireline and wireless solutions have supported the evolution of this vertical market by seamlessly providing robust fiber cabling infrastructure network solutions to support critical operations. These solutions can accomplish several things:

- Alert you to changes made to the physical layer infrastructure

- Guide technicians in performing work orders

- Provide technicians real-time circuit information wirelessly during remote trouble-shooting

These things are critical for the operations and maintenance teams to optimize network efficiency. They also provide security in their control network process, monitoring fiber links in a plant environment in real time: MACs, remote locations, service orders, etc. The first step in the plant’s environment is to conduct a return on investment analysis. This will assure the companies with operational efficiency and that can be accomplished by deploying an imVision system.

Another way to do that is to look at industrial rooms for deploying a edge data centers to reduce the time to service with high efficiency. Its proven success to handle harsh, cold temperatures (−40° C) and high humidity environments without supplementary cooling (direct expansion or chilled water) demonstrates it can be deployed for capacity need where ever it is needed.Remote terminal units can acquire necessary data from field instruments. They transfer the data to a central location in real time using wireless communications systems. This provides the oil and gas market enhanced coverage and capacity with real-time alarms in their network, thus improving quality of services needs into operations technology. CommScope will facilitate field-to-office cooperation.

It’s an exciting time to be in the oil and gas industry. How we can help you?